Funges coating for sump waterproofing work in t...

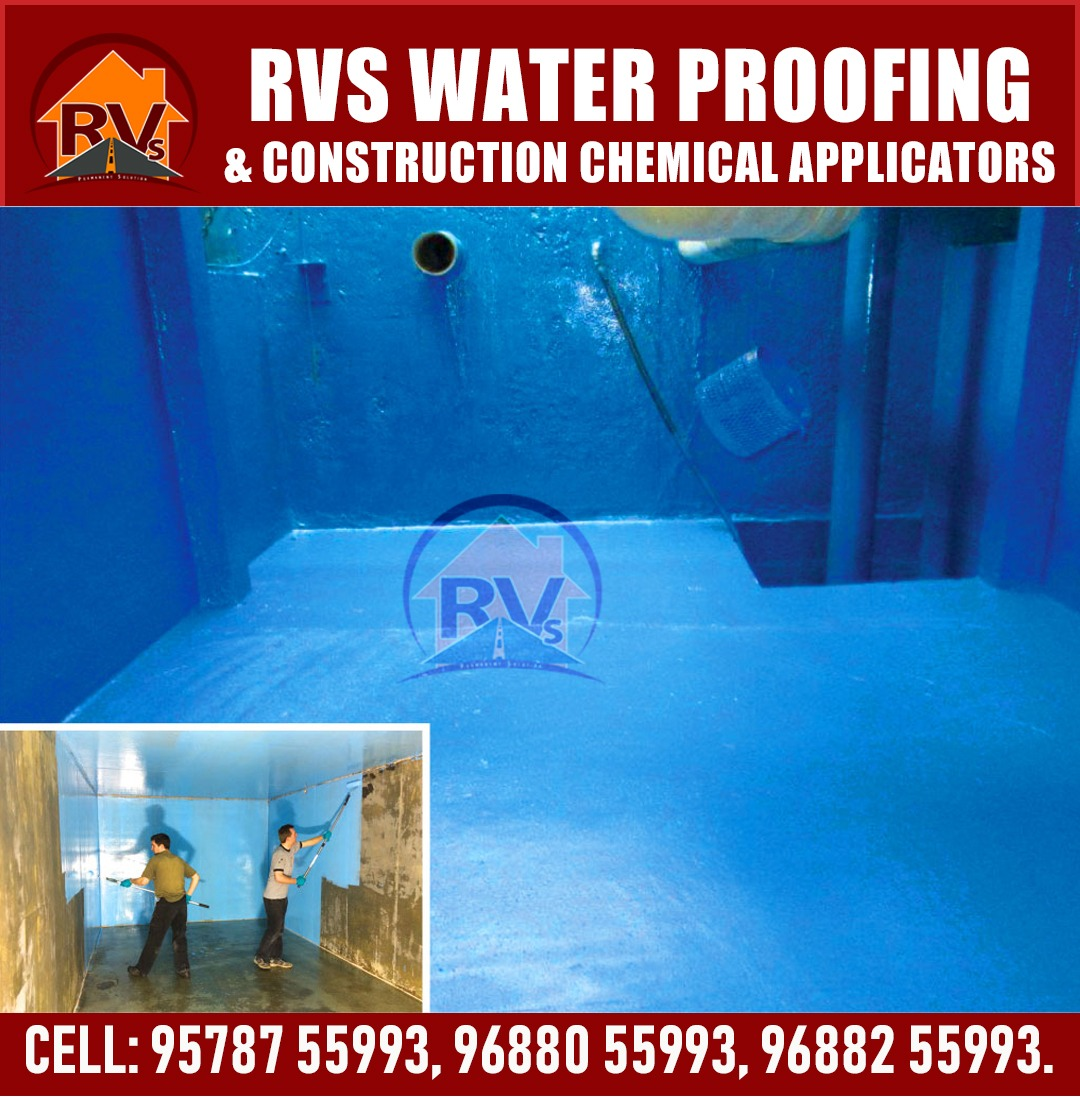

Funges coating for sump waterproofing work in thuvakudi RVs waterproofing construction chemicals Application Saturate the cured cement surface with water. . Liquid component of the acrylic polymer bound cementitious waterproof coating material is measured out into a bucket. . The powder (cementitious) component is added slowly while stirring continuously to the liquid in the required proportion (usually 1 liquid : 2 powder by weight or as prescribed in the manufacturer's datasheet). Stirring is very important to avoid formation of lumps. . Brush apply the mixture on the substrate. . Allow the coating to dry. . Cure the coating with water. . Once cured, saturate the coating with water. . Stir the contents of the 2 part epoxy first in their individual containers to a uniform consistency and then mix the the 2 components in the required proportion (usually the 2 components are available in pre-measured packs or as prescribed in the manufacturer's datasheet). Addition of water as per the datasheet. . Apply the first coat of the epoxy system with a brush. . Allow the coating to air-cure for about 6-8hours. . Brush apply the second coat in a direction perpendicular to the direction of application of the first coat. . Allow the coating to air-cure and harden. The above process takes about 48 hours and water can be filled in the tank after about another 48 hours.

Keywords

Subscribe for latest offers & updates

We hate spam too.